This week I’m taking a small detour from the Side Chair Build series to finish up my posts on grain orientation and wood movement. The principles of grain orientation and wood movement have a direct impact on milling part blanks from the larger board, which will be the subject of the next post in the Side Chair Build series. I recommend that you also go back and read the first post on grain orientation and wood movement to get a complete overview. In that post I talked about how the amount of wood movement varies relative to the grain orientation.

In summary, wood moves most in the tangential plane (tangent or parallel to the growth rings); wood moves less in the radial plane (perpendicular to the growth rings or “heart to bark”); and for the purposes of most woodworking wood does not move at all in the longitudinal plane (the long grain running vertically up a board). Knowing this I showed how to orient a mortise and tenon joint made up of a turned rung tenon mating with a mortise in a turned leg. With straight, turned parts each part can rotated to the correct grain orientation at the time of assembly.

However, with parts that have at least one flat plane, we must look for boards with the correct grain orientation and mill the part from it. In a chair these parts include the rear legs, slats, runners, and arms.

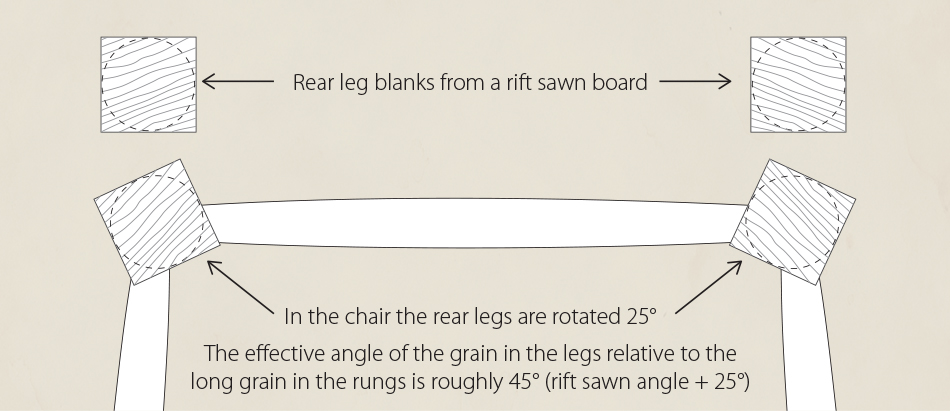

For rear legs we cut blanks from boards that are rift sawn. When the legs are assembled in the final chair they will be rotated about 25°. When you add the angle of the rift sawn grain to the angle that the legs are rotated you end up with grain that is roughly 45° relative to the long grain of the rungs. If you go back and look at the first post about grain orientation you’ll see that this matches the compromise grain orientation of the front legs to the rungs.

Slats are best cut from a board that is quarter sawn. A slat milled from this board will have the radial grain in the tenon (which has less movement than the tangential plane) running parallel to, and complementing the long grain in the leg (which has no movement).

The same applies to the runners which are also milled from quarter sawn boards.

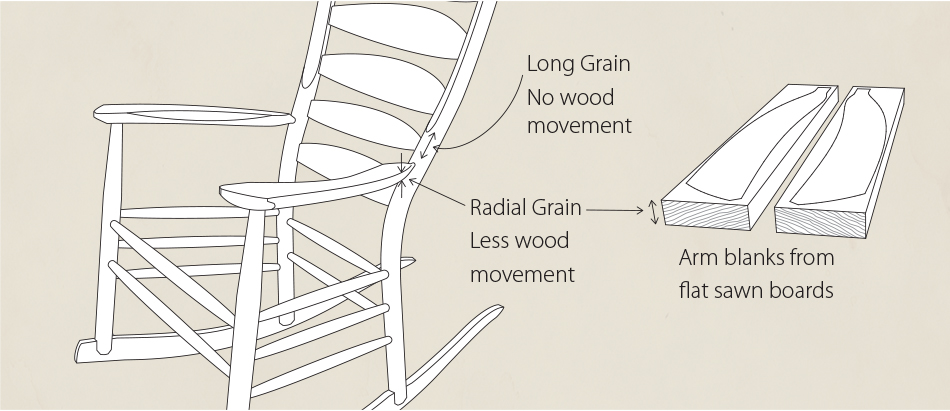

Arms are milled from flat sawn boards. This aligns the radial grain (less wood movement) in the arm tenon with the long grain (no wood movement) of the rear leg.

Paying attention to the grain orientation of blank chair parts is one of the first steps in the process of creating strong, lasting joints.

Related post: Grain Orientation and Wood Movement, Part 1